Injection plastic cup and box

Injection plastic cup and box

Injection plastic cups and boxes are widely used in a variety of industries and applications due to their durability, affordability, and versatility.

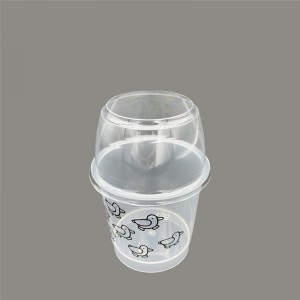

Injection plastic pudding cup

Description

Here are some of the most common scenarios where injection plastic cups and boxes are used:

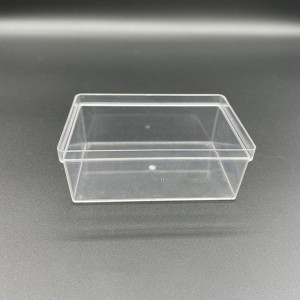

Food Packaging: Injection plastic cups and boxes are commonly used in the food industry for packaging a wide range of products, from pre-packaged salads and fruits to condiments and sauces.

Pharmaceuticals: Injection plastic cups and boxes are used to package various pharmaceutical products, such as pills, liquids, and ointments.

Cosmetics: Injection plastic cups and boxes are also used to package cosmetic products, such as creams, lotions, and makeup.

Industrial: Injection plastic cups and boxes are used in various industrial applications, such as for storing and transporting small parts and components.

Advantages of Injection Plastic Cups and Boxes:

Durability: Injection plastic cups and boxes are made from high-quality plastic materials that are durable and resistant to impact and wear-and-tear.

Affordability: Compared to other packaging materials, such as glass or metal, injection plastic cups and boxes are much more affordable, making them an attractive choice for cost-conscious businesses.

Customization: Injection plastic cups and boxes can be molded into a wide range of shapes, sizes, and designs, making it possible to create custom packaging solutions that meet specific needs.

Barrier Properties: Injection plastic cups and boxes offer excellent barrier properties, making them ideal for packaging products that need to be protected from light, moisture, and other environmental factors.

Lightweight: Injection plastic cups and boxes are lightweight, making them easy to handle, transport, and store.

Recyclable: Many injection plastic cups and boxes are recyclable, making them an environmentally responsible choice for businesses and consumers.